18

Hamburg, March 18, 2021

Supply chain delays, March 2021

We would like to provide you with an overview of the ongoing delays in ocean freight and the impact on international supply chains. While in Europe the situation has become largely stable and predictable despite continued local regulatory restrictions in land transport, the availability of equipment, cargo space capacity and the ongoing adjustment of schedules continue to pose major challenges to the international ocean freight market.

Review:

In the spring of 2020, the lockdown began in China and gradually spread throughout the world, with a corresponding decline in sales and global trade. Then, in June 2020, freight volumes surged again, initially between Asia and the USA. With the increasing recovery of trade routes, carriers and shipping companies quickly tried to make capacities available again. However, these were soon no longer sufficient to cover the demand. What factors led to the current situation?

Reduction of available containers

During the first lockdown, some trade routes came to a standstill. As a result, containers were stranded in places with low demand which reduced the number of FCLs at ports that were heavily frequented. At the same time, shipping companies began to reduce their container stocks during this period which further limited the containers available for the transport of goods. The shortage at high-demand locations caused freight rates to quickly shot upwards during the recovery phase.

Port congestion

In addition, many ports had to reduce staff at terminals and in the transportation sector during the lockdown period due to hygiene guidelines and spacing requirements resulting in a reduction in port handling and terminal capacity. As a result, there have been backlogs in the ports which have reduced the reliability of the schedules to a record low. This has also affected the national transport. The consequences are delays, missed departures and lower volumes shipped.

Reduced vessel capacity

During the first lockdown period, vessels were specifically taken off the market for maintenance. There were also transports by ship that had to be interrupted due to Covid cases among the crew. Both of these factors created an additional shortage of available capacity.

Change in consumption

As a result of the continued unpredictable development and the change in people’s consumption during the pandemic, there has been a change in demand in trade worldwide. Shipping companies are trying to adapt to the change in demand in global trade by shifting capacity, especially cargo space and equipment, to serve routes that are in higher demand. However, this has led to a further shortage of freight capacities, accompanied by price increases for the shipping companies.

Today‘s Situation:

On the west coast of the USA, there are now drastic delays, among other things due to an import volume that has been increasing for months. At the same time, there are not enough containers available for export shipments as the – delayed – returning empty equipment is only partially available for this purpose but is also shipped empty back to Asia, again associated with increased rates. The Agriculture Transportation Coalition has already submitted a request for regulatory intervention to US President Biden.

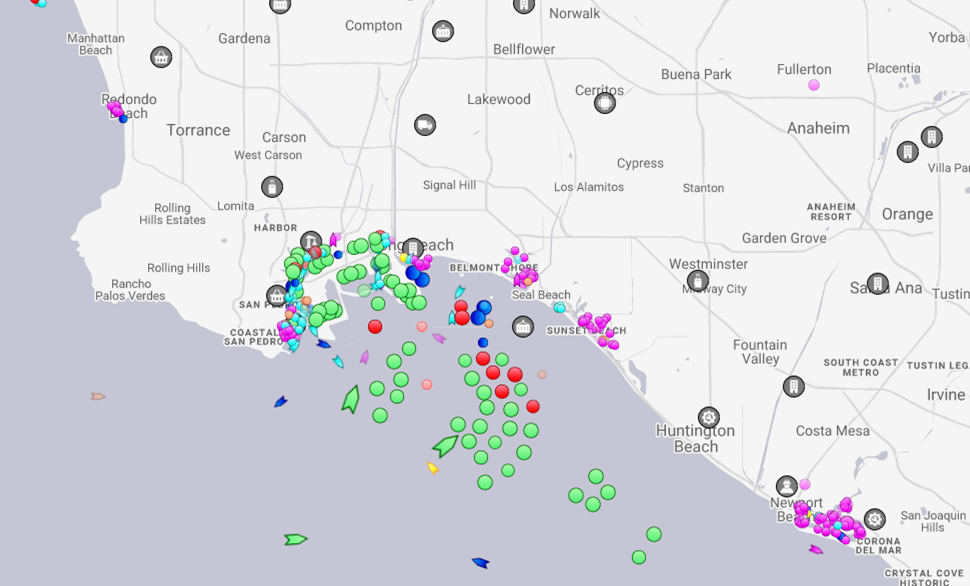

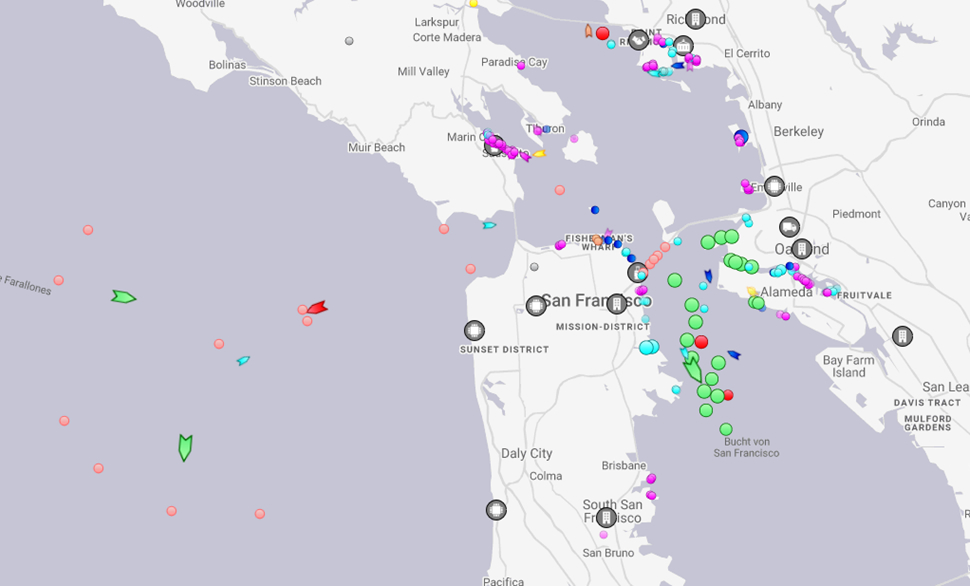

Numerous ships are lying in various ports, waiting and the clearance of the ships is sometimes accompanied by considerable delays. In Oakland, the current waiting time is 3-6 days on average, in Long Beach already up to 14 days.

In the meantime, the port calls of the ships are varied so that not every ship calls at every originally planned port. This again has an impact on the capacities for outgoing containers. As a result, bookings are sometimes postponed several times with delays of several weeks.

Long Beach, Screenshot – www.marinetraffic.com (March 2021)

Oakland, Screenshot – www.marinetraffic.com (March 2021)

Meanwhile, similar problems are also being reported from the East Coast of the USA. In addition to the well-known restrictions due to changed schedules and a capacity bottleneck for equipment, the East Coast was also hit by various winter storms which further restricted handling at the ports.

We expect the situation to remain challenging for the next 2-3 months and do not anticipate a quick recovery.

We recommend the following measures:

- We request that demand planning and call-off be carried out as early as possible

- Please allow at least a further 4 weeks lead time in addition to the known lead times before the desired shipping and/or delivery date

- Please contact us with any questions you might have or we could help to work out alternative routes. We will be happy to advise you!

With kind regards,

Bösch Boden Spies GmbH & Co. KG

Quellen:

- https://de.kuehne-nagel.com/-/services/seefracht/globale-herausforderungen-seelogistik

indicated waiting times: „my KN“ – seaexplorer - https://agtrans.org/wp-content/uploads/2021/02/AgTC-The-Current-Export-Crisis_02-12-21-1.pdf

PDF - 696 Kb

PDF - 696 Kb